On this page, you can see some of the Fluitecnik projects.

Wind tunnel for transformer tests

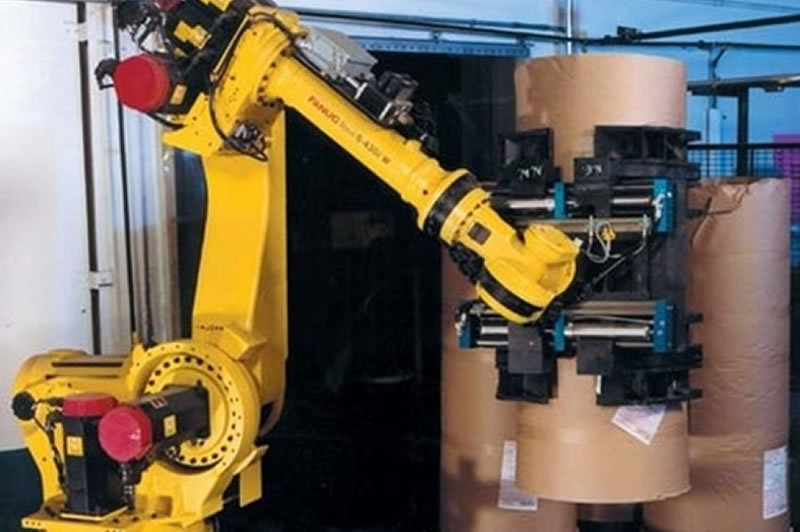

Robotic Cell

Robot installation

Installation of enclosures and doors

Installation of conveyor belts and elevetators

Control through HMI + CPU electrical cabinet

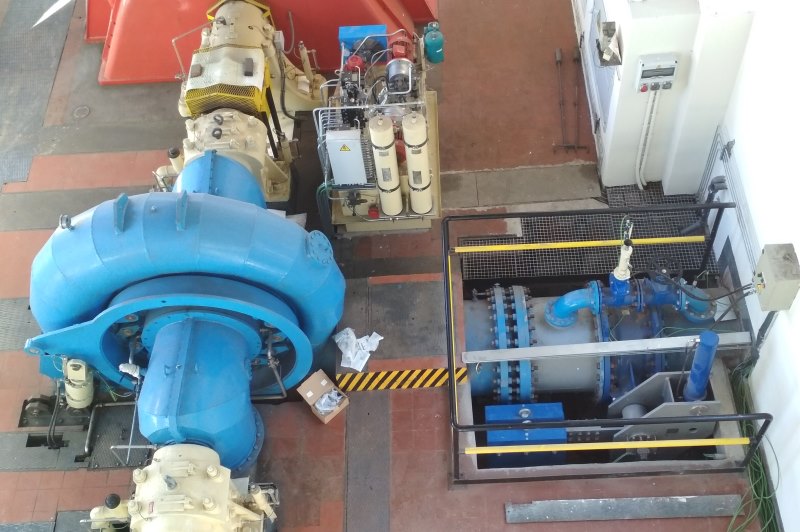

Converter cooling installation with water

Installation of pumping and cooling of glycol water for temperature control of converters.

Control by electric cabinet and mobile remote registers.

Robot Automation

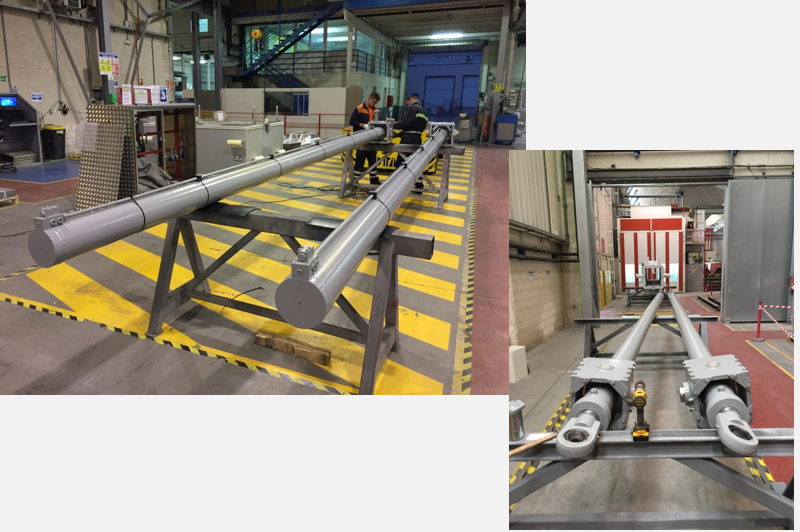

Installation designed to perform bending, forming, punching, checking and unloading of the FRAME BACK TUBE.

It is a robot that is responsible for the displacement of the FRAME BACKUP TUBE in the different phases from bending to unloading.

The entire installation is surrounded by an enclosure with two access doors built into the maneuver with safety latches.

Hydroforming Press

Main technical characteristics:

- It is a vertical free fall press, with 4 cylinders of 320 / 300×400 (manufacture of our client).

- Maximum working pressure 320 bar.

- Installed power: 75Kw main engine.

- 1500 l deposit.

- Hydroforming system, consisting of high pressure multiplier, up to 2500 bar.

- Control system of the multiplier, loop closures in pressure and position, with Moog technology.

If you have any questions, do not hesitate to contact us