ENGINEERING

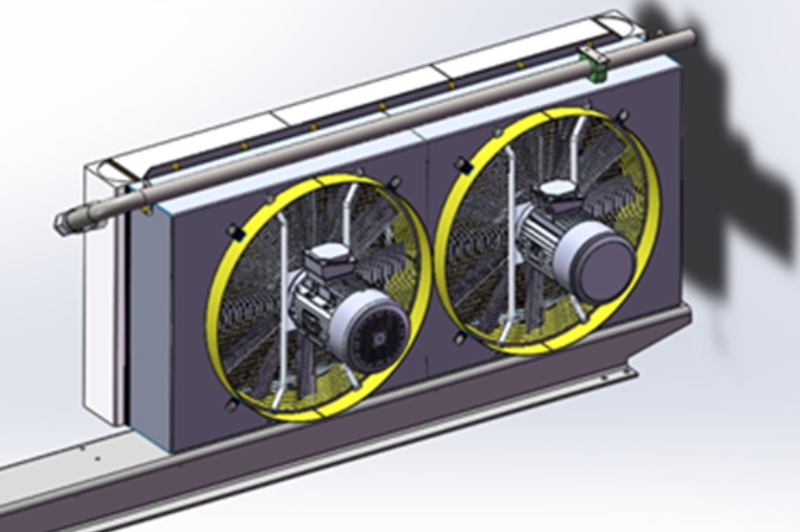

The constant and continuous collaboration with the client and the fulfillment of its specifications are fundamental to guarantee the design of the specific product that each client needs. Our designs and products are reliable, robust and durable, as are the machines on which they are mounted. Our “know-how” is our greatest value and is always available to the client in the search for new solutions.

Our products are approved, certifying that they have been designed, documented and manufactured to comply with design assumptions, specific standards and other technical requirements.

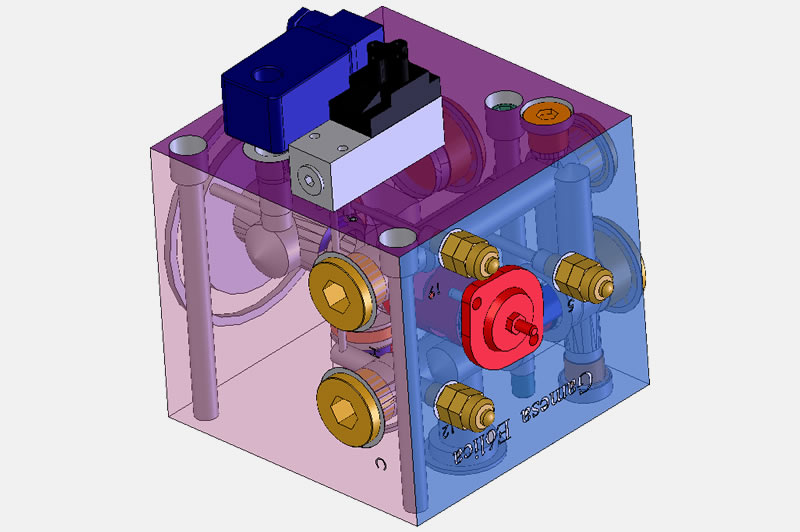

Our Engineering Department prototypes following the specifications provided by the client. We design, test and assemble the prototypes and when we get the validation of the customer, that product is produced in serie.

To take the prototyps we use test benches and all the documentation collected (data sheets, drawings, certifications, test reports, etc.).